News

WIRE 2018 Report

The issue of Industry 4.0 has dominated many exhibits during this year's WIRE exhibition which took place from April 16 - 20, 2018 in Düsseldorf. We at schwer +kopka could present a number of practical applications in Cold Forming 4.0 on our stand as well as on those of several renown machine builders.

A number of subjects have been given additional momentum as a result of the new IATF 16949. This norm is putting special emphasis on the state and the condition of machinery under the term TPM (Total Productive Maintenance), as this a very important factor in the efficient production of high quality parts. Our new MES modules "Maintenance" and "Machine Condition Monitoring" are geared towards supporting many of the requirements of IATF 16949. Routine machine maintenance jobs are automatically set due by the actual machine running hours or at a planned date ensuring that preventive maintenance is carried out in time. Additional machine sensors which are connected to our process monitoring systems measure and monitor the "health" of the machines. Such sensors measure temperatures, vibration, consumption of energy and compressed air and permanently register how well the machine is doing. All sensor measurements and the complete set of process data are archived and documented in our PTO data base for future reference and retrieval.

The machine builders Nedschroef Machinery and WAFIOS Umformtechnik showed several machines in operation which featured an SK process monitor in conjunction with condition sensors for bearing temperature, energy and air consumption, flow of coolants, etc. Up to 16 condition sensors with industry standard output of 0-10 VDC or 4-20 mA can be connected to each monitoring unit. National Machinery showed on their booth an Industry 4.0 data center which was networked with several cold forming and thread rolling machines working in remote locations such as the US. All machines were equiped with SK process monitors and sent their process and production data to our SK-go! software installed in the booth.

The MES-software SK-go! benefited from a newly designed and intuitively operated graphical user surface called Xpress. Every user can create their own individual dashboard, meeting individual demands for information from many available modules.

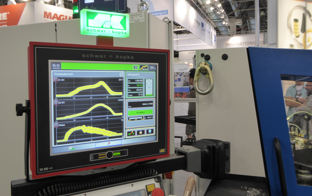

The first models of the new generation of schwer + kopka process monitoring systems also premiered at WIRE. The newly developed hardware with modern high performance processors and the latest capacitive 16:9 touch screens build the foundation for future improvements. The systems also introduce our new operating philosophy. The user interface aligns even more with logical work flows and always shows supplementary information to the currently used screens.

We wish to thank the again many visitors for their interest. Please see below some impressions from the show: