Machine Terminals with Process and Tool Monitoring

All monitoring terminals of the SK series are housing the complete electronics for the evaluation of the sensor signals, the visualization of the process monitoring and the data acquisition in a space-saving, shapely flatpack. When designing the monitoring systems, we placed great emphasis on reliable, trouble-free operation even in the typically harsh environmental conditions of a production plant.

A superior heat management ensures that the electronics consume as little energy as possible, thus keeping operating temperatures low and extending the service life of the electronic components. The PC-based systems work fanless and with the latest Windows operating systems.

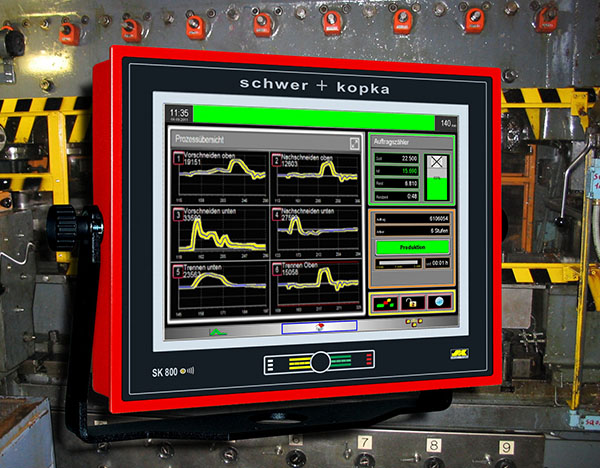

Monitoring Terminal SK 800

- compact flat device with large 15" touch color display

- for process monitoring and tool protection

- integrated, fanless PC technology

- Windows 10

- up to 32 analog channels

- 5 binary inputs / 5 outputs (expandable)

- connection for rotary encoder

- connection for servo module (SSI)

- Mandonic envelope automatic

- Foxmatic monitoring technology

- Mandon® technology with automatic suggestion system

- M-apps for analyzing machine performance

- SK-Puzzlemaster expert system

- roller setup aid with DMI/DMA (Die Match Indicator)

- Trend, Q-Factor, tool protection with binary sensors

- SK-Cockpit multifunction display

- RFID key for access authorization

- very easy to operate

- Quick-Install technology

- connection for production data acquisition with SK-go!®

- OPC-UA interface module

- ready for Industry 4.0

- prepared for PTO 4.0 process data documentation

- prepared for machine condition monitoring

- dimension 385 W x 325 H x 135 D (mm)

The functions are partly optional.

Monitoring Terminal SK 500 Tec-Pac

- compact flat device with large 10,4” touch color display

- for process monitoring and tool protection

- integrated, fanless PC technology

- Windows 10

- up to 16 analog channels

- 5 binary inputs / 5 outputs (expandable)

- connection for rotary encoder

- connection for servo module (SSI)

- Mandonic envelope automatic

- Foxmatic monitoring technology

- Mandon® technology with automatic suggestion system

- M-apps for analyzing machine performance

- SK-Puzzlemaster expert system

- Roller setup aid with track control DMI/DMA (Die Match Indicator)

- Trend, Q-Factor, tool protection with binary sensors

- SK-Cockpit multifunction display

- RFID key for access authorization

- very easy to operate

- Quick-Install technology

- connection for production data acquisition with SK-go!®

- OPC-UA interface module

- ready for Industry 4.0

- prepared for PTO 4.0 process data documentation

- prepared for machine condition monitoring

- dimension just 290 W x 240 H x 115 D (mm)

The functions are partly optional.

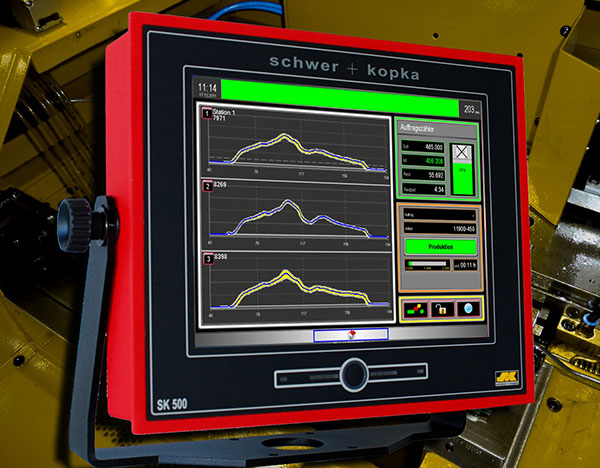

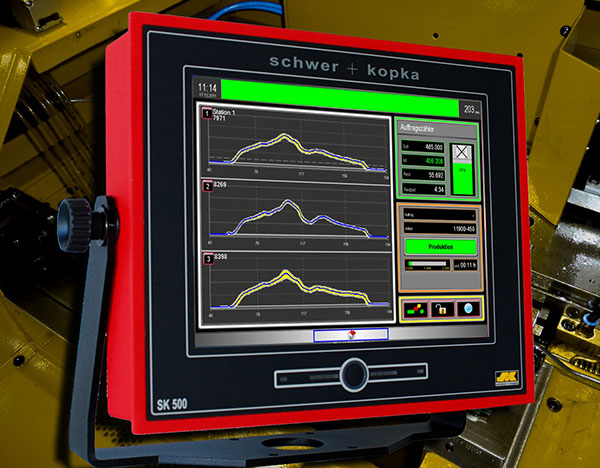

Monitoring Terminal SK 500

- compact flat device with large 10,4” touch color display

- for process monitoring and tool protection

- integrated, fanless PC technology

- Windows 10

- up to 8 analog channels

- 5 binary inputs / 5 outputs (expandable)

- connection for rotary encoder

- Mandonic envelope automatic

- Foxmatic monitoring technology

- SK-Puzzlemaster expert system

- thread roller setup aid with DMI/DMA (Die Match Indicator)

- Trend, Q-Factor, tool protection with binary sensors

- SK-Cockpit multifunction display

- RFID key for access authorization

- very easy to operate

- Quick-Install technology

- connection for production data acquisition with SK-go!®

- OPC-UA interface module

- ready for Industry 4.0

- prepared for PTO 4.0 process data documentation

- prepared for machine condition monitoring

- dimensions just 290 W x 240 H x 115 D (mm)

The functions are partly optional.

Monitoring system SK 5.12

- 360° Process monitoring for tool and machine protection

- Powerful dual core processor

- 12,1” capacitive multi-touch with bright LED display

- Up to 16 analog inputs with highly dynamic signal amplification

- 5 digital inputs and outputs

- EasyTouch control with operating mode display

- Interface for incremental rotary encoders

- Ready for IIoT / MES / MDC / PDC

Basic features:

- Multi-Cockpit user interface

- 8k envelope monitoring with pattern recogintion

- Automatic measurement window

- Dynamic automatic start after machine stop

- Signal stabilization during speed deviations

- Idle stroke detection for thread rollers

- Flexible sorting functions

- Triple-Trend technology (time, stroke, PQI)

- PTO replay

- Job-, Tool-, Auto2-counter

Special features:

- SPC-, Sorting-, Batching- and Additional-counter

- Monitoring-Modules: A+, M+ and Triple profile

- Production statistics

- Screenshot to USB

Monitoring system SK 4.10

- 360° Process monitoring for tool and machine protection

- Powerful dual core processor

- 10,1” capacitive multi-touch with bright LED display

- Up to 8 analog inputs with highly dynamic signal amplification

- 5 digital inputs and outputs

- EasyTouch control with operating mode display

- Interface for incremental rotary encoders

- Ready for IIoT / MES / MDC / PDC

Basic features:

- Multi-Cockpit user interface

- 8k envelope monitoring with pattern recogintion

- Automatic measurement window

- Dynamic automatic start after machine stop

- Signal stabilization during speed deviations

- Idle stroke detection for thread rollers

- Flexible sorting functions

- Triple-Trend technology (time, stroke, PQI)

- PTO replay

- Job-, Tool-, Auto2-counter

Special features:

- SPC- and Sorting-counter

- Monitoring-Modules: A+ and M+

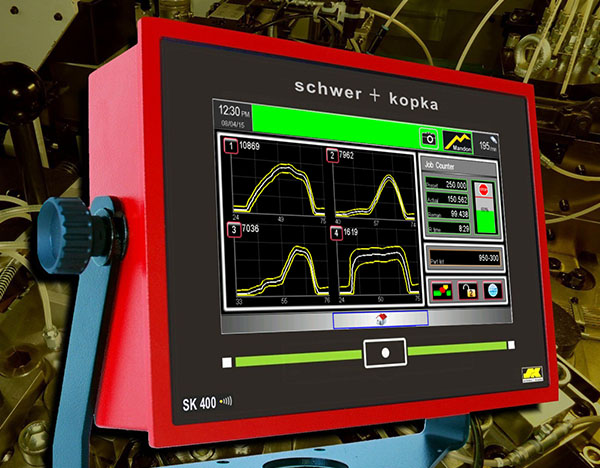

Monitoring Terminal SK 400

- compact flat device with 7" touch color display in 16:9 format

- for process monitoring and tool protection

- up to 16 analog channels

- 5 binary inputs / 5 outputs (expandable)

- connection for rotary encoder

- Mandonic envelope automatic

- Foxmatic monitoring technology

- SK-Puzzlemaster

- Mandon® technology with automatic suggestion system

- roller setup aid with DMI/DMA (Die Match Indicator)

- Trend, Q-Factor, tool protection with binary sensors

- SK-Cockpit multifunction display

- RFID key for access authorization

- very easy to operate

- Quick-Install technology

- connection for production data acquisition with SK-go!®

- OPC-UA interface module

- ready for Industry 4.0

- prepared for PTO 4.0 process data documentation

- dimensions just 230 W x 165 H x 60 D (mm)

The functions are partly optional.