SK Energy Management System

Our MES software and process monitoring systems have been making an important contribution to resource-saving production for many years. This offering is now supplemented by the EMS module for recording, analysing and monitoring energy consumption.

The system can be used separately or in combination with our MES software SK-go!® In particular, linking energy consumption with actual machine runtimes and the produced quantities allows detailed analyses of consumption patterns, provides direct approaches for saving measures, avoids unnecessary consumption and makes relevant key figures available.

Through the on-line connection of customary electronic consumption meters, the system offers a variety of acquisition options for all common types of energy such as electricity, compressed air, gas, etc.

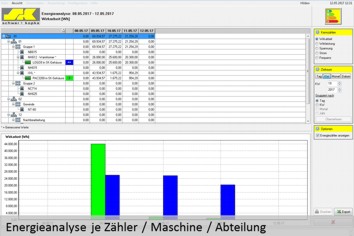

SK analysis of energy consumption

The hierarchy of your energy consumers and the existing counters or meters is exactly mapped in the data base, from the factory to the departments and groups down to the individual machine.

In addition, you can easily define how the energy consumption is recorded:

- virtually via estimated load and no-load consumption

- virtually via a reference measurement of load and no-load consumption

- digitally via electronic and connectable measuring instruments

The energy analysis allows you to analyse and compare consumption per counter, machine, machine group or department. The energy analysis contains a logbook for each counter, which visualises the measured counter readings chronologically.

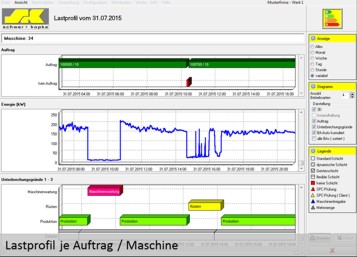

Load profile shows energy consumption and machine running properties

Matching machine running and downtimes precisely with the energy sensors shows precisely the consumption for the individual operating states.

From the load profile you can read:

- Does a plant require unnecessary energy, although it does not produce at all

- How large are e.g. losses due to leakage (compressed air)

- What are the effects of energy-saving measures (comparison before/after)

Using the load profile, consumption can be analysed on the basis of the machine's behaviour. For example, the energy consumption profile shows whether the automatic shutdown of a machine's auxiliary consumers a few minutes after a machine stop leads to measurable savings in consumption. All SK monitoring systems are equipped with this delayed shutdown function by default.

Energy counters

Different types of energy counters can be used for the connection to the MES software SK-go!®. If a counter has an RJ45 interface, it can usually be connected via OPC-UA.

Counters with a pulse output can be integrated via an additional Mini-PLC (Siemens hardware). The pulses are recorded via the PLC, where they are counted and transferred as consumption via an Ethernet interface. The type of energy is irrelevant. Common counter types include:

- Flow sensors (gas/compressed air/water)

- Energy transducers (electricity/active power/reactive power/etc.)

- Temperature sensors

- and much more